Description

Description

It is applicable to a wide range of samples. Based on its efficient grinding technology and rich accessories, it adopts a two-steps grinding method of rotating knife-ring sieve system, which can perform dry and wet grinding of soft, hard, brittle and fibrous samples in a very short time.

Sample type: Soft, elastic, fibrous, water-bearing, oily, fatty, dry sample.

Application fields: Agriculture, environment, soil, electronics, RoHS testing, coal, chemistry, plastics, medicine, feed, grain, dry plants.etc.

Features

Diversified application, efficient sample preparation

Ecological environment protection: plants (root, stem and leaf, etc,) sample preparation, C.H.N determination;

Coal, coatings sample preparation; ash content, thermal measurement;

Identify the nitrogen composition and protein composition of feed and food;

Secondary fuel, rubbish, plastic, electronic elements, the determination of harmful substances.

Grinding art for special samples

Plastic and rubber samples will become brittle and easy to grind in liquid nitrogen condition.

The distance ring sieve and automatic vibratory feeder can be used for grinding heat-sensitive samples such as paint, resin.

The rotor and ring sieve with wear-resisting coatings can be used for grinding rigid and corrosive materials such as fertilizers, chemicals.

Automatic feed device and large sample receiver

It can be equipped with an automatic feed device, which can guarantee highly homogeneous grinding results and avoid the risk of sample feed overload.

The ground samples are collected in a collecting pan, which is convenient for collection without sample loss and prevents cross contamination of samples.

Diversified accessories

Rotor

The rotor has three options: 24 teeth, 12 teeth, and 6 teeth. The 24 teeth is for the crushing of fine sample, while the 12 teeth for general sample and the 6 teeth for coarse massive sample.

Ring sieves

Final fineness depends on the different aperture ring sieve. We also provide the reinforcing screen to enhance the stability of the ring sieve.

The material of all the rotors and the ring sieves not only has stainless steel but also the heavy-metal-free for choice to meet different laboratory requirements.

The rotor and the ring sieve are chosen according to the properties of the samples, the required final fineness and subsequent analysis.

We offer a special ring sieve with shear function. For most materials, about 80% of the samples can reach the fineness of less than the half aperture size of the sieve used.

Specification

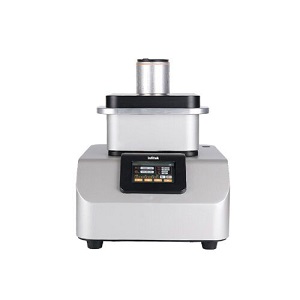

Model GM-G200

Feed Size <10mm

Final Fineness < 40μm

Speed 6000-18000rpm

Peripheral Speed 31.4~94.2m/s

Rotor Diameter 98.5mm

Ring Sieve 0.08, 0.12, 0.20, 0.25, 0.50, 0.75, 1.00, 2.00mm

Collecting Pan Volume 900ml ( The volume of the sample collected is no more than 300ml)

Rated Power 760W

Electricity 220V, 50/60Hz

External Dimension 400*506*495mm

Package Dimension 620*620*770mm

Net Weight 38kg

Cryo Grinder, GM-L200

Cryo Grinder, GM-L200

Reviews

There are no reviews yet.